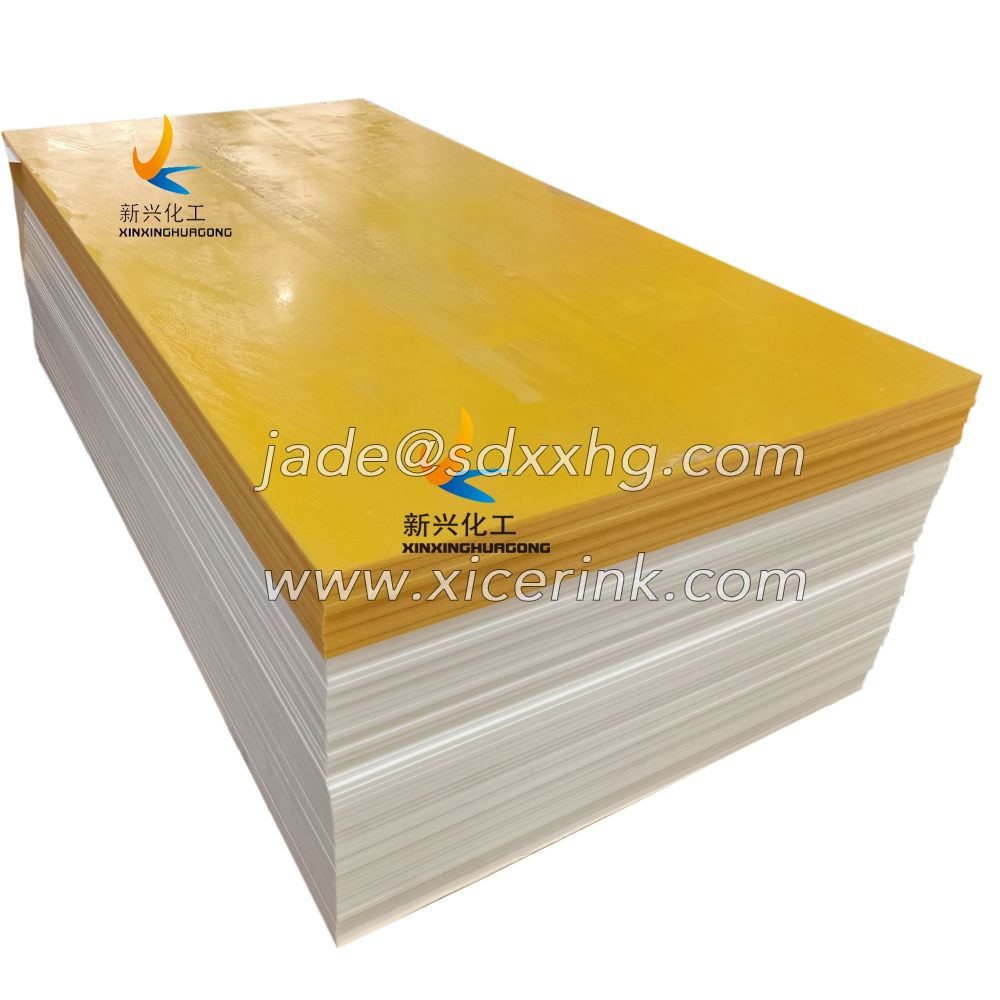

HDPE 500 sheet HDPE sheet PE300 PE100

Brand: XINXING

hdpe sheet professional manufacturer :

HDPE Sheets offer a wide range of benefits including high-impact strength, durability and the ability to resist corrosion from weather, alcohols and acids. Xinxing Plastics offers HDPE Sheets in black and natural colors for boating, commercial kitchens, and other use cases.

PE-HD

PE100

PE300

PE500

High Density Polyethylene

High Density PE

Product Overview

HDPE is an engineerina plastic that is often underestimated and.although HDPE is popular, it is sometimes confused with other engineering plastics. HDPE is a shortened name for High Density Polyethylene and available in two main grades. 300 and 500 grade The higher the HDPE grade number the higher the density of the plastic is which improves the performance of the product. Although HDPE is unable to be bonded with currect adhesives. HDPE can be welded with purpose designed and economical welding equipment.

DESCRIPTION

What are HDPE Plastic Sheets?

HDPE is a strong, durable plastic that is able to withstand different kinds of weather, acids, alcohols, and impact, making it a popular choice across a wide variety of industries. Companies looking to improve their sustainability are also often turning to HDPE to fit their needs, since it is easy to recycle and reuse.

Are HDPE Sheets FDA Compliant?

HDPE Sheets are FDA compliant, making them a popular choice in commercial kitchens. They are dishwasher safe and easier to clean than other cutting board alternatives such as wood.

What is HDPE Panel Used For?

HDPE Panels have a wide array of use cases including the following:

Marine and Boating

Storage (such as fuel tanks and storage sheds)

Piping Systems

Swimming Pools

Folding Chairs and Tables

FDA Approved Cutting Boards

Wood Alternative for Furniture

Is HDPE Sheet Flexible?

HDPE polymer chains are relatively linear and are closer together, resulting in a stiffer plastic when compared to LDPE. These same qualities make HDPE a strong and durable plastic, which is able to resist heavy impact.

Can You Glue HDPE Sheets?

Previously, HDPE needed to be melted in order to be fused together. With recent advances in technology, new epoxy-based glues have emerged that allow HDPE to be glued to other surfaces, such as PVC or steel. However, the instructions on the glue container must be followed, since the HDPE sheets needs to be prepared before the glue can successfully applied.

How strong are HDPE Sheets?

HDPE has a high strength to density ratio, making it a strong plastic, that is able to handle high-impact stress. It is also scratch resistant and able to withstand solvents, chemicals, and alcohols, making it an ideal plastic for various use cases.

SIZE

black, 48" x 96" sheets with gauge sizes ranging from 1/8" to 1"

natural: 48" x 96" sheets with gauge sizes ranging from 1/16" to 4"

natural: 48" x 120" sheets with gauge sizes ranging from 1/8" to 2"

natural: 60" x 120" sheets with gauge sizes ranging from 1/8" to 1"

2440x1220mm

2400x1200mm

2000x1300mm

8'x4'

8 feet x 4 feet

96 inch x 48 inch

96 inch x 24 inch

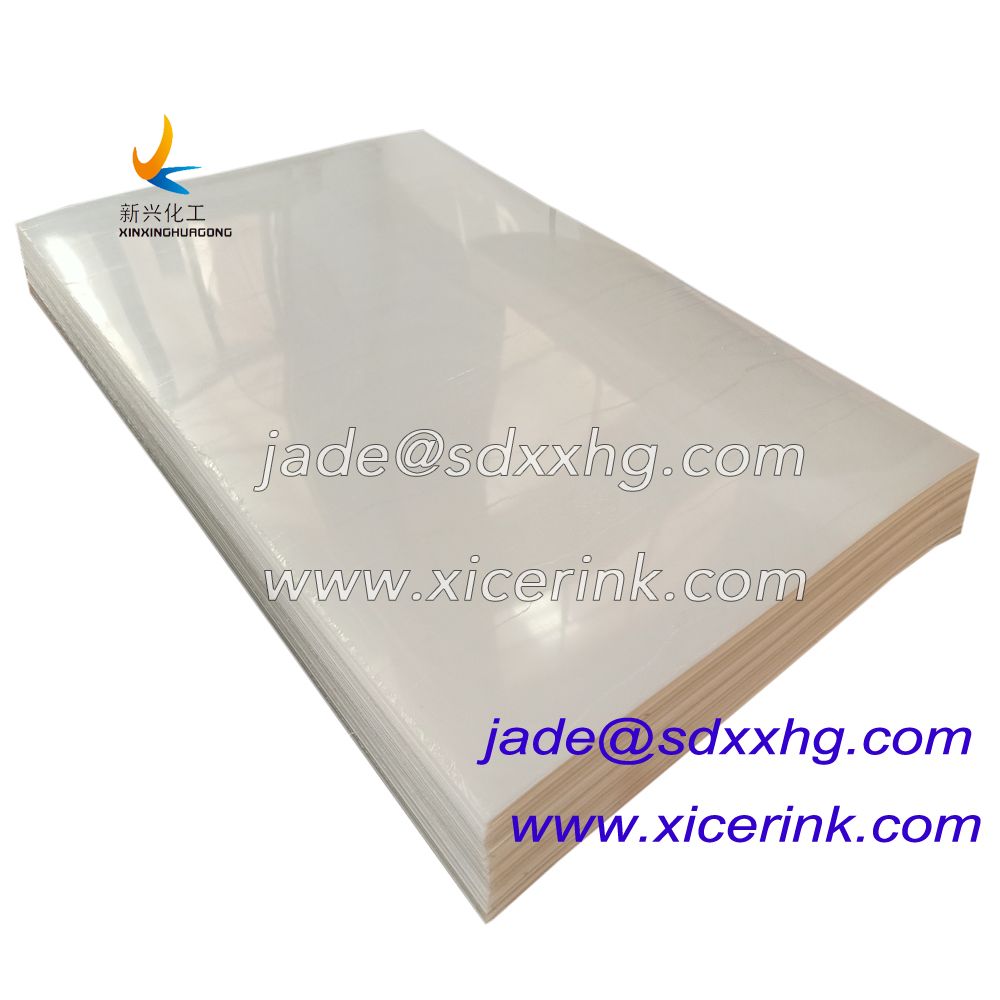

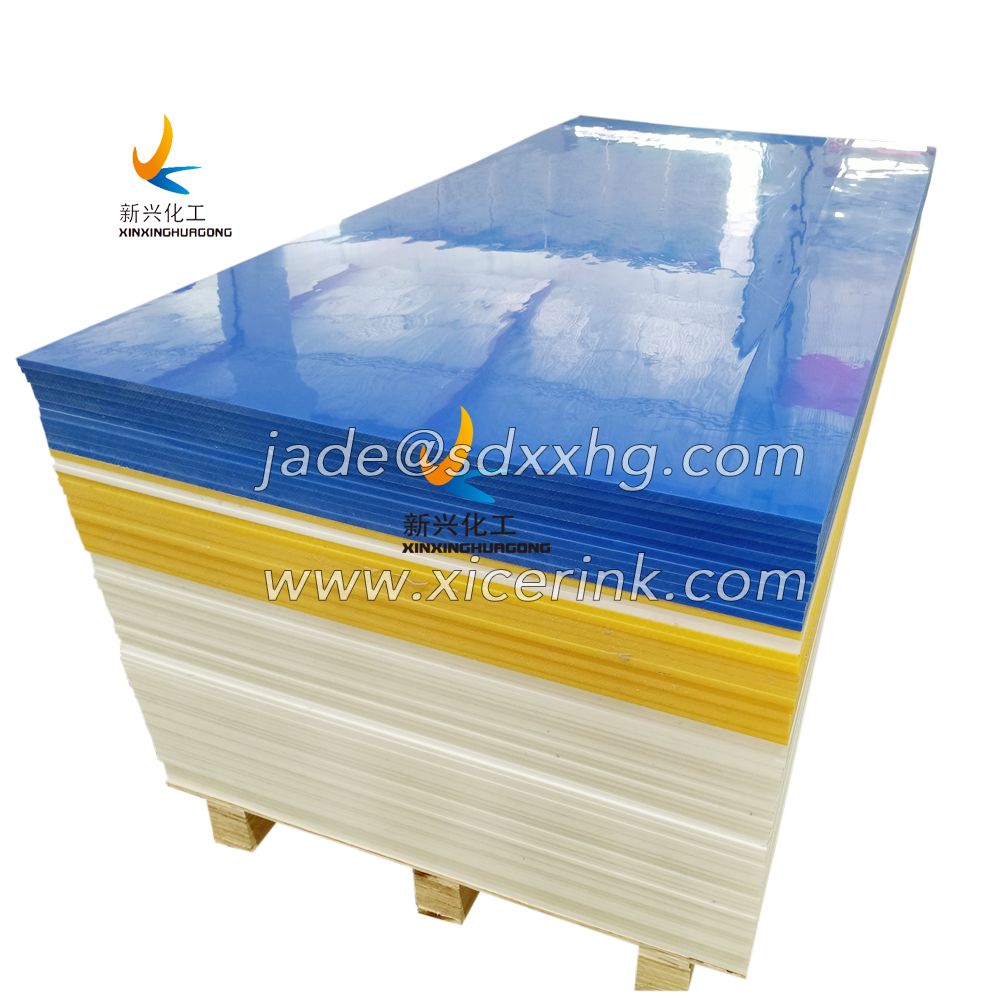

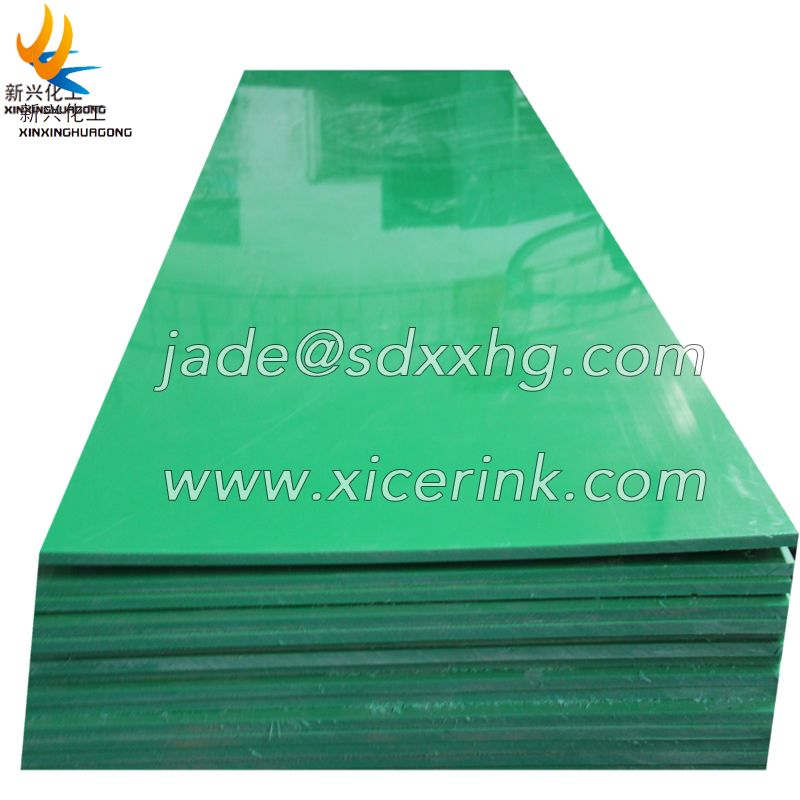

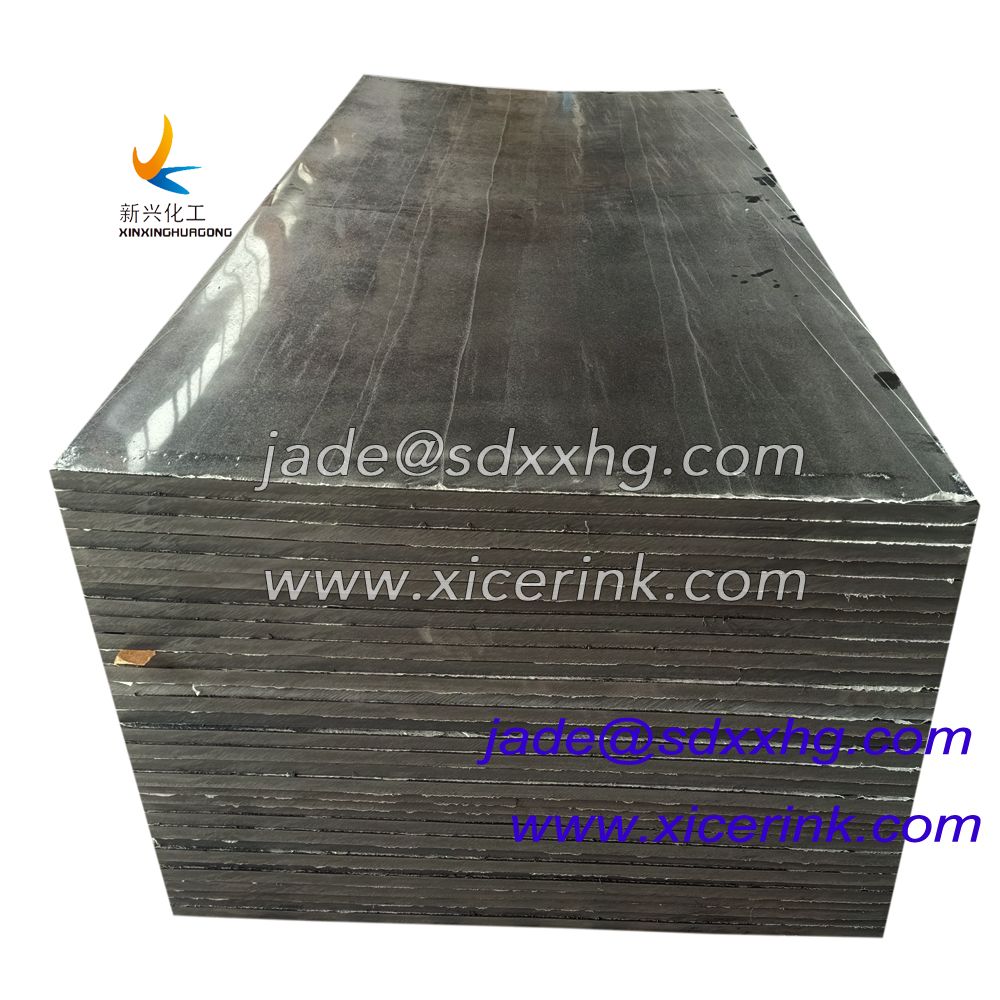

COLOR

Our HDPE Sheets are available in:

Black

Natural (White)

Yellow – UV Stabilised

APPLICATIONS

HDPE Applications

With a low coefficient of friction, long term durability, as well as high impact strength, it’s no wonder HDPE is the product of choice for so many applications within marine biology, packaging, industrial, plumbing, food and beverage, consumer industries and more.

Marine Use

HDPE is most commonly known to be used in marine wear applications. Resistance to acid, odor, moisture, mildew and stains make it a one of a kind plastic solution for marine usage. HDPE is used in marine applications such as boating seats and floors (when covered from UV lights), cabinetry, counter tops and walkways.

Storage Applications

Its light weight, durability, flexibility and toughness make HDPE a great solution for many storage applications including bottles, bottle caps, food storage containers, bins, laundry detergent bottles, and water cans. Fuel tanks for vehicles, plastic bags, storage sheds, and lawn and garden products are also produced from HDPE plastic. Due to its high chemical resistance, HDPE is used to make geomembranes for hydraulic applications (such as canals and bank reinforcements) and chemical containment.

Piping Systems

HDPE has the durability and chemical resistance to make it an ideal plastic solution for many piping systems including chemical resistant piping systems, corrosion protection for steel pipelines, geothermal heat transfer piping systems, water pipes for domestic water supply, and agricultural processes.

Industrial

Industrial industries all over the nation use HDPE plastic to produce tough and durable products such as mechanical parts, tank linings and wear strips. These products rely on the impact resistance and super tensile strength of HDPE products, which make them more durable and reliable.

Consumer

HDPE plastic is used to make a myriad of consumer products such as swimming pool installations, backpacking frames, banners, folding chairs and tables as well as hard hats. Products such as hula hoops, plastic lumber and fireworks are produced using HDPE, for its flexibility and toughness. FDA compliant grades of HDPE also make several products for kitchen use including cutting boards, cheese molds and molds for frozen food.

Boarding

One of HDPE’s most commonly used applications is its use in boarding material such as arena board (puck board) in hockey rinks and moisture resistant body boards for use in morgues.

Marine Use: boating seats, floors, cabinetry, counter tops, walkways

Storage: bottles, bottle caps, food containers, plastic bags, bins, laundry detergent bottles, fuel tanks, watering cans, lawn and garden products, storage sheds, geomembranes for hydraulic applications (such as canals and bank reinforcements) and chemical containment.

Piping Systems: chemical resistant piping systems, corrosion protection for steel pipelines, geothermal heat transfer piping systems, water pipes for domestic water supply, agricultural processes

Industrial: mechanical parts, tank linings, wear strips

Consumer: swimming pool installations, backpacking frames, banners, folding chairs and tables, hard hats, hula hoops, plastic lumber, fireworks

Boarding: arena board (puck board), moisture resistant body boards for morgues

Food and Beverage: FDA approved cutting board, cheese molds, frozen food molds

DATA SHEET

Xinxing is the largest Group manufacturer of engineering plastics in China. Xinxing's main products include UHMWPE & HDPE sheets, double colour HDPE sheets and parts, as well as custom machined plastic parts such as, UHMWPE Synthesis of ice, PE hockey shooting board, plastic ice rink barrier, ICE RINK system, ICE HOKCEY RINK SYSTEM, FLOORBALL RINK, SOCCER REBOUNDER etc. Email: jade@sdxxhg.com

Product Name: HDPE 500 sheet HDPE sheet PE300 PE100